The future may not just be around the corner—it may already be here. Sustainability is now a critical issue for the textile industry, with the clothing sector being one of the world’s most significant contributors to environmental degradation.

Alarmingly, around 40% of garments produced each year go unsold.

This equates to about 60 billion pieces destined for storage or, worse, disposal. Even halving this overproduction wouldn’t be enough to prevent billions of unsold clothes from ending up in landfills.

Overproduction: Fashion’s Dirty Secret

Overproduction is a pressing issue within the fashion industry. In a January article for The Guardian, Lucianne Tonti exposed overproduction as the industry’s “dirty secret.”

The main culprits behind overproduction are demand uncertainty and brands’ inclination to over-manufacture to avoid stockouts and missed sales.

Predicting exact consumer demand is notoriously challenging, so brands tend to err on the side of caution by producing surplus stock, hoping to sell it.

Massive sales of 50%, 60%, or even 70% off become commonplace in a bid to clear out unsold inventory.

Traditional production models have long pipelines, which often require garments to be manufactured for three to six months before reaching stores.

These long production timelines accumulate work-in-progress (WIP) items, which prevents us from adapting to real-time demand changes.

Factories are designed to maximize efficiency, where machinists are typically trained for specific tasks, enhancing production efficiency.

However, this specialization also makes the process rigid. A machinist’s role in a traditional setup is highly focused: after completing a bundle, the garments are passed to the next specialist in line, creating a slow-moving assembly system.

Overloaded production lines hinder a timely response to customer demand. With this setup, brands find adjusting supply to actual customer buying behavior nearly impossible, resulting in a costly and environmentally harmful disconnect.

A New Approach: Embracing ‘On-Demand’ Production

At Bunker Mentality, we have long aimed to bring a unique style and dynamic color to the golf world. We followed a traditional model for two decades: producing seasonal collections, distributing them wholesale, and establishing a steady retail presence in Europe and Japan.

Early on, we also explored the direct-to-customer (DTC) approach through online channels, thanks in part to a forward-thinking partnership with Nottingham University, which helped launch our first e-commerce site.

The pandemic further highlighted the advantages of our DTC model. We delivered to 55 countries, proving the potential of a direct approach and ultimately reinforcing our shift towards on-demand manufacturing.

This evolution allows us to align customer needs directly with production, avoiding overproduction.

How ‘On-Demand, One-Piece’ Production Works

Four years ago, we began a partnership with an advanced factory specializing in ‘on-demand, one-piece’ production.

This facility does not rely on traditional mass production. Instead, garments are manufactured individually based on customer orders—there is no surplus stock and no endless pipeline.

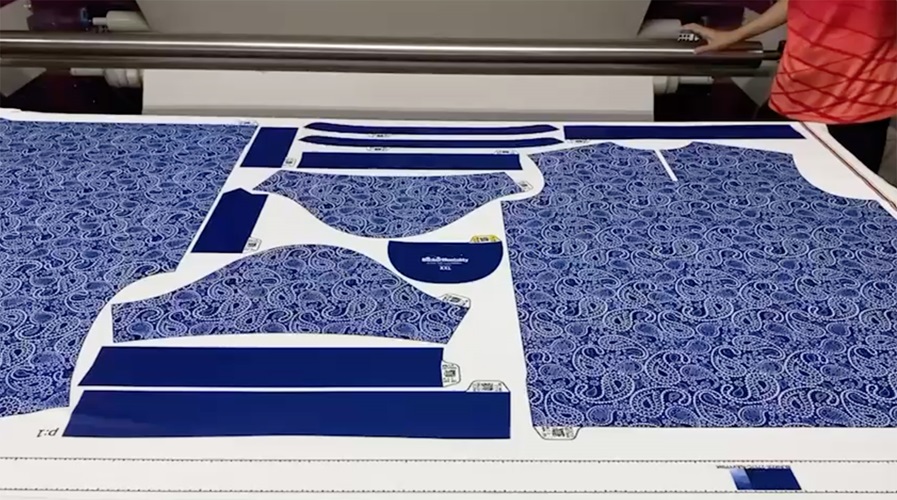

Orders flow directly from our website to the factory through specialized software that handles each process step.

The fabric is printed for each order, then cut, assembled by multi-skilled machinists, quality checked, and shipped straight to the customer. This cellular model is agile and capable of meeting demand without creating waste.

In our on-demand system, the ‘waiting for stock’ concept disappears. Every order is custom-made, so customers get precisely what they ordered without delays.

Waiting a few extra days for a sustainably produced polo shirt becomes a small sacrifice in the quest to minimize environmental impact.

The Advantages of On-Demand Manufacturing

The benefits of on-demand, one-piece production are transformative:

- No Overproduction: Garments are made to order, avoiding surplus production and resource waste.

- Reduced Carbon Footprint: Only items that customers purchase are produced, cutting back on energy, water, and transportation emissions.

- Minimal Packaging: Orders go directly from the factory to the customer, eliminating the need for extra packaging layers.

- No Need for Warehousing: By bypassing stock storage, we reduce the environmental toll associated with long-term storage and distribution logistics.

The on-demand model simplifies our supply chain. Previously, our sales team drove thousands of miles yearly to meet with retailers and promote seasonal collections.

We would then order bulk stock from the factory, ship it across continents, warehouse it, and finally deliver it to hundreds of retailers. Each stage required substantial resources, from diesel fuel and electricity to packaging materials.

With on-demand production, every garment is manufactured only when a customer orders.

This model allows us to keep designing without worrying about storage or unsold stock. Today, we are no longer limited to a fixed range – our collection can now expand with as many designs as we create.

In 2025, we plan to introduce fresh polo shirt designs every month, which would have been impossible under the traditional model.

Always Available: Size Inclusivity Through On-Demand

One significant benefit of on-demand production is that all sizes are perpetually in stock. Under traditional production, sizes at the extremes (such as very small or very large) tend to sell out quickly, resulting in frustrated customers.

In an on-demand model, we no longer face this issue—every size is available to every customer every day of the year. In fact, we have now extended our size offer from X-Small to 4XL.

Sustainable Growth Through On-Demand Direct To Consumer

In the last twenty years, the internet has transformed retail, making it possible for brands like Bunker Mentality to adopt a DTC approach that reduces environmental impact.

Without the need for physical retail stores, we’re already reducing our ecological footprint. On-demand production is the next logical step toward a more sustainable future, bridging customer needs and eco-friendly production practices.

Of course, the on-demand model may not suit every category, but it can work wonders for many. It represents a forward-thinking approach that requires a shift in mentality from brands, retailers, and consumers alike.

Building a Better Model, One Garment at a Time

On-demand manufacturing offers more than a significant reduction in carbon footprint—it also sets a new standard for responsible production.

By tailoring manufacturing to real-time demand, we’re creating an industry model that prioritizes longevity and environmental consideration.

In our pursuit of an improved system, we’ve discovered that we can align style and sustainability, crafting clothing that reflects our philosophy: in golf, style matters.

Dynamic colors, graphic designs, and attention to detail remain central to our brand, and on-demand production allows us to uphold these values without compromise.

In summary, the world of fashion is shifting. On-demand production presents a more sustainable way forward, balancing customer satisfaction with ecological responsibility.

Every order placed in this system reflects a conscious choice—for the customer, for us, and for the planet. With this approach, we can shape a fashion industry built not on excess but on purpose and respect for our world.

We’re making a tangible impact by meeting consumer needs precisely and sustainably, one piece at a time.

Let’s continue to build a future that respects style and sustainability – a future we can all look forward to.